In the frame of the work packages fully dedicated to the design and development of the Inflatable Structure system (IS) and the Cool Gas Generator System (CGG) for ICARUS re-entry demonstrator, ATMOS Space Cargo, design authority of the IS, in collaboration with HDES, design authority for the CGG, executed the Inflation test campaign.

This dedicated test effort, performed at ATMOS and HDES premises in Summer 2025, aimed at the verification of the seal seems and performances of the various IS layup materials adopted in the design configuration, as well as at the verification of a demonstrator of the CGG component.

Test outcomes allowed to verify the IS concept and manufacturing, as well as the perfromance of the CGG confirming the adequateness of the design solutions adopted in the ICARUS project.

Pillow tests

- Evaluate the pristine inflation and unfolding inflation performance of an IS breadborad in the form factor of a pillow replicating the concept in terms of material stack up and manufacturing solution.

- Among the test objectives there was the verification of the leakage control and seam sealing effectiveness, and burst testing of the stack up.

Pillow test setup

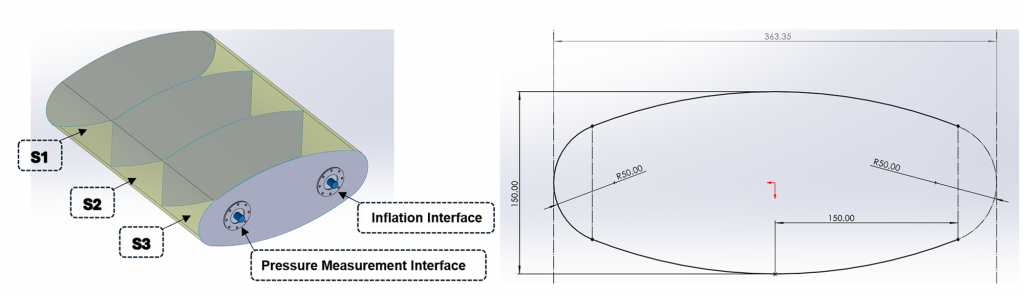

- A representative inflatable with all major Inflatable Structure features (Minimum radius: 50 mm, Volume: 19.5 l, Length: 450 mm);

- Two clamped pneumatic interfaces for sensing and inflation respectively;

- A representative breadboard of a Cool Gas Generator cartridge, including the igniter and the piping.

Pillow interfaces (left) – Pillow dimensions (right)

Test

- A total of Three test campaigns (2 in HDES and 1 in ATMOS premises) were carried out.

- The test campaign explored multiple material combination, Particularly, during pillow test #3 executed at HDES premises, three variants tested with different inner/outer bladder materials:

- HDES Test PILLOW 1: Kapton Polyimide inner and outer bladder.

- HDES Test PILLOW 2: Silicone inner bladder, and Kapton Polyimide outer bladder.

- ATMOS Test PILLOW 3: Kapton Polyimide inner and outer bladder with one less inner patch.

Outcomes:

- The Kapton Polyimide PILLOW demonstrated superior performance, reaching 19 kPa internal pressure with successful unfolding tests. Leakage issues are being resolved, with smaller breadboards already showing leak-free performance.

- Testing confirmed that Polyimide is the preferred bladder material, requiring application on both sides of the IS for effective sealing.

- Leakage is limited to front and back seams not present in flight models, while sealant-induced stiffening was observed locally at seams.

- Future improvements will focus on adopting higher-strength fabrics and ensuring all seams are fully sealed to enhance overall durability and airtightness.

Pillow test #3

Leave a Reply